- Posted On May 3, 2023

- No Comment

So as the check lists started to have all their boxes ticked it was time for the complete build inspection. For this I had to bring the car to the Inspection. There we went over the car, checked off the fixes I had done since the rolling chassis inspection. Brakes were tested, looking for leaks and for movement in the panel that the master cylinders are mounted too. After that the inspector took off for a 20 minute drive, checking steering wheel return, brake performance and general car handling as bump steer etc. All that was passed and the brakes even surpassed the 0,8 G retardation demand, the best one showed 1.0 G and I got the comment that I could move the brake bias slightly towards the rear for even better performance.

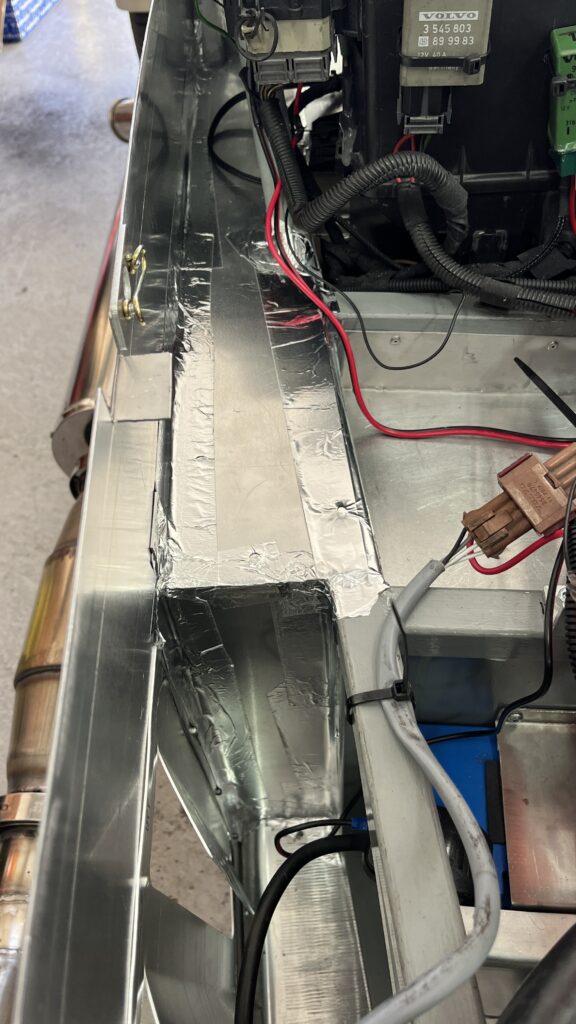

A few minor fixes was brought up, one was to seal up the gaps between the “cockpit” and the engine room. For the larger gaps I made alu pieces and riveted them in place.

The smaller gaps was sealed with a body sealant and then covered with aluminium tape.

I also needed to add a heat shield to the exhaust. I had already planned on this so it was just to dust off the old cad files and make a few minor changes and then I had it lasercut and folded up. Mounted to the silencer supports and the forward V-band clamp.

About a week later it was time for the mandatory noise test. It is done driving in second and third gear, at 40-50 km/h and then 7 meters before the microphone full throttle is applied. The measurements is done on both sides of the car and twice for each side and gear so for my car it was a total of 8 passes. The limit is 84 dBa which the car passed with a good margin.

Now all I have to wait for alot of paperwork to be completed and then its time for the single vehicle approval where I hopefully will be assigned licence plates for a fully road legal car. 🙂